![]()

ROTARY DYNAMICS REMANUFACTURED ENGINES

Rotary Dynamics Engines are fully disassembled and

inspected for evidence of failure. A thorough cleaning process ensues,

consisting of macro degreasing, removal of residual carbon build-up and

complete ultrasonic cleaning. External component finish is restored to

automotive industry standards for corrosion-resistant coatings. All

components are inspected and compared to Mazda service specifications.

Only top quality components which are found to be in compliance are used in the

reassembly process. Non-compliant or non-salvageable components, primarily

rotors and housings are discarded. All seals, gaskets and critical rotor

components are replaced as a matter of course. Rotary Dynamics backs all

stock engine configurations with a one year warranty from the date of purchase.

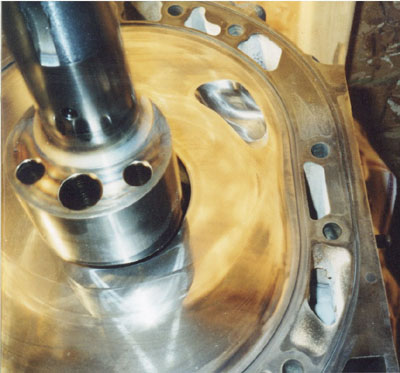

Left: old rotor vs. freshly cleaned rotor Right: ported side

plate during reassembly process

|

YEAR |

APPLICATION |

PART NUMBER |

PRICE (CDN) |

PRICE (US) |

|

1979-1985 |

12A, Stock1 |

E17001 |

$2250 |

$1960 |

|

1984-1985 |

13B, Stock |

E17002 |

$2250 |

$1960 |

|

1986-1988 |

13B, Stock 6

port, Non Turbo |

E17003 |

$1800 |

$1565 |

|

1987-1988 |

13B, Stock 4 port, Turbo |

E17004 |

$1950 |

$1700 |

|

1989-1992 |

13B, Stock 6

port, Non Turbo |

E17005 |

$1850 |

$1625 |

|

1989-1992 |

13B, Stock 4 port, Turbo |

E17006 |

$1950 |

$1700 |

|

1993-1995 |

13B, Stock 4 port, AT |

E17007 |

$2300 |

$2025 |

|

1993-1995 |

13B, Stock 4 port, MT |

E17008 |

$2300 |

$2025 |

CORE DEPOSIT -

$400-$1300 CDN/US, please inquire for further detail prior to ordering

Shipping is

available worldwide. Please inquire for further detail.

Additional

Engine Services

PORTING - Various porting levels

available upon request.

ROTOR APEX SEAL

CONFIGURATION - In 1986 Mazda introduced a newly-designed 2mm 3-piece apex seal

in an effort to improve sealing and ultimately compression. Newer apex seals are of the 2-piece

construction, however still with a thickness of 2mm. In higher boost applications or to salvage a pair

of good rotors, an apex seal groove modification can be performed. The end result in higher boost

applications is a set-up with thicker apex seals which are signficantly more resistant to shear and

bending. This is a highly recommended service for boosted applications or situations where a

pair of rotors with slight damage to the apex seals grooves could be reused. This service is

available as an upgrade over the above pricing.

Notes:

1. 12A engine configurations differ between 1979 and 1985.

Considering the age of the first generation RX7, there exists a possibility

that the original engine may have been replaced or modifications made at some

point. As a result, the exact configuration may not necessarily match the

original equipment specifications. If in doubt, a core must be provided

in advance, in order to properly assess the configuration of the engine.

2. All engines identified as "stock" are guaranteed to be a

direct fit to an original, unmodified application.